Start-up and first year

The two brothers were born on the island of Reksta in Flora, and they came to Helle at an early age. With time they would build the biggest business in the community. Jørgen had gone to metalwork trade school, when he in 1937 took employment as a repairman at Helle Teglverk (brickyard). In his free time he helped people with various types of metalwork. In 1947, he started up a workshop of his own, built of brick from the brickyard, which he picked from the sea by the quay, stones which had fallen into the water during loading. The production began in 1948. Olav took mechanical and technical education. Gradually he became involved in the business. They called it Brødrene Klausen (the brothers Klausen).

The first production facilities were 60 square metres. Additions were built in 1952, extensions, and a second floor in 1968. To begin with, they did various metalwork, and repairs of equipment. And they made aerial cableways, tractor equipment, lifts, and kicksleds. They tried to build a tractor of their own, the model Vestland. In the 1950s they equipped and repaired fishing vessels.

Progress after 1970

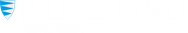

Into the 1960s it was not unusual for a business in the heavy engineering industry to offer several services and products. But then more specialization took over, which was also the case at Brødrene Klausen. This required more space, and the business was moved from Bøvikneset to Bøvika, to the west of the old facility. The municipality of Fjaler helped build a new industrial facility in 1972. Later three other production facilities were built, the last one in 1996. The business bought up the municipal investment in the facilities. A bigger sea terminal has also been built. From the quay, pieces weighing up to 80 tons can be loaded.

Brødrene Klausen found a new market when it in the 1970s became a subcontractor for other industrial enterprises. They made units for shipyards, f. ex. those in Florø and at Leirvik. These ship parts have large dimensions, the largest ones weighing 80 tonnes.

The business has produced steel constructions for smelting plants and ferry bridges for the public roads administration. And it has made parts for the offshore oil industry. The last two-three decades it has made fish farms and taken on various sub-contracts for other companies in other places.

The work force

At the end of the 1960s, around 20 were on the payroll. The number rose to 115 in the 1970s. Around 2000, the work force was around 75. The workers organized a union of their own in 1974.

Subsidiary company at Svelgen

In 1990, the subsidiary company Klausen Industrier Svelgen A/S was established. Klausen Mekaniske Verksted had before this had travelling fitters in contract with Elkem A/S (smelting plant) at Svelgen. This was the basis for the subsidiary company, which employs 12 persons. They are doing repair work for the smelting plant and others, and produce electrode parts, steel cases around the electrodes.

After 1998

1999 was a good year, making ship units at full capacity, while the following year had reduced activity and lay-offs. In 2001, the order books were again full and employment secured for the whole work force until 2004.